地图 - 热线

地图 - 热线

地图 - 热线

地图 - 热线

- 服务热线 - 15392885678 15069779222

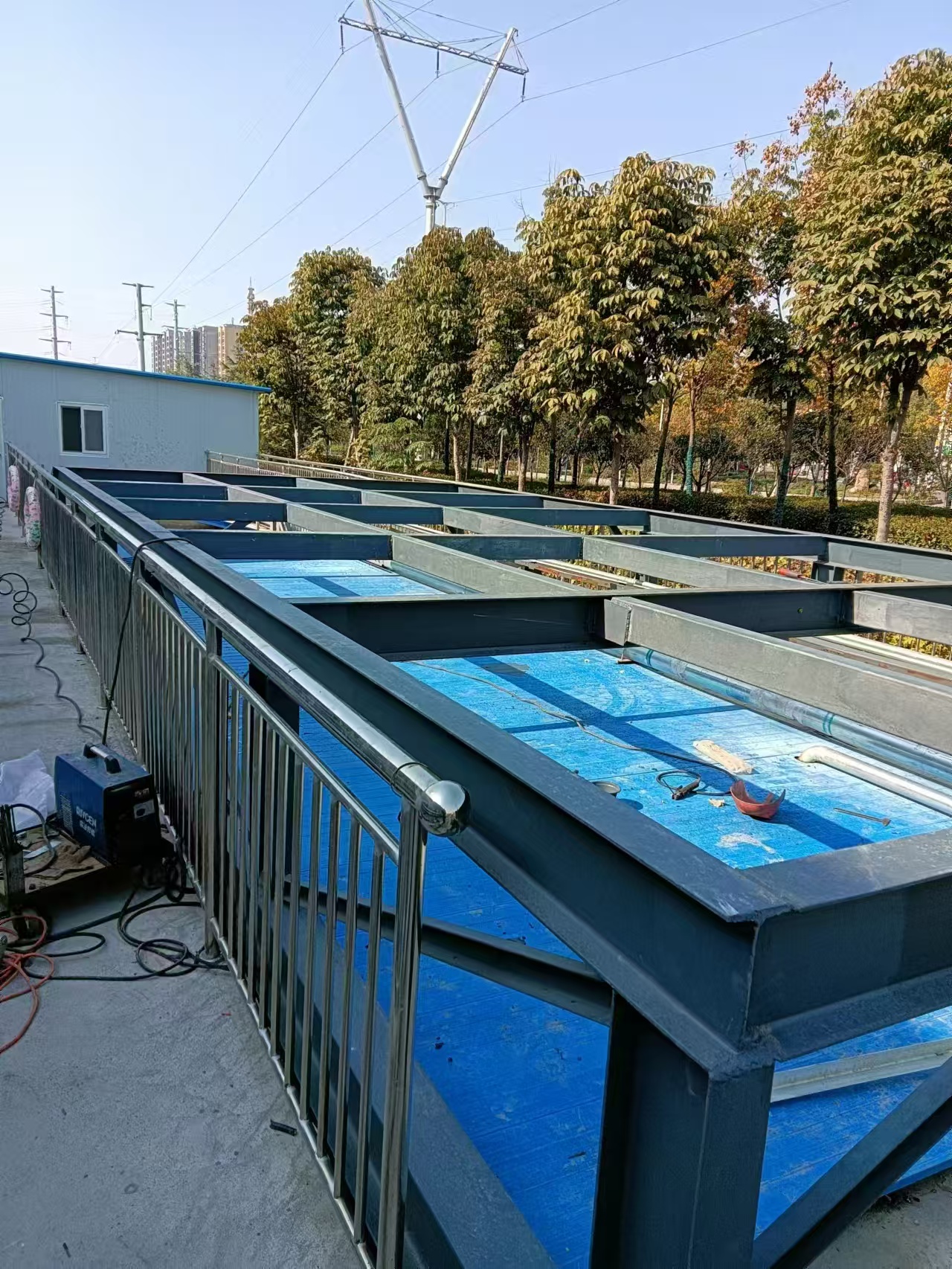

生物除臭设备滤池是一种利用微生物代谢活动降解恶臭气体的环保装置,其核心在于通过构建适宜的微生物生存环境,将硫化氢、氨气、挥发性有机物等臭气成分转化为无害物质。该技术以生态友好、运行成本低、无二次污染等优势,广泛应用于垃圾处理、污水处理、畜牧养殖等领域。

Biological deodorization equipment filter is an environmentally friendly device that utilizes microbial metabolic activity to degrade odorous gases. Its core lies in creating a suitable microbial living environment to convert odorous components such as hydrogen sulfide, ammonia, and volatile organic compounds into harmless substances. This technology is widely used in fields such as garbage treatment, sewage treatment, and animal husbandry due to its advantages of ecological friendliness, low operating costs, and no secondary pollution.

滤池的工作流程可分解为三个关键阶段:臭气收集与传输、生物降解反应、尾气排放。首先,恶臭气体通过密闭收集系统被导入滤池底部,经由布气装置均匀分散至填料层。这一步骤的设计至关重要,均匀的气流分布能确保微生物与臭气充分接触,避免局部过载或处理盲区。

The workflow of the filter can be decomposed into three key stages: odor collection and transmission, biodegradation reaction, and exhaust emissions. Firstly, the odorous gas is introduced into the bottom of the filter through a closed collection system and evenly dispersed to the packing layer through a gas distribution device. The design of this step is crucial, as even airflow distribution can ensure sufficient contact between microorganisms and odors, avoiding local overload or blind spots in treatment.

填料层是滤池的核心反应区,通常由多孔性惰性材料构成,如陶粒、火山岩或复合有机载体。这些材料不仅为微生物提供附着表面,其孔隙结构还能截留气体中的颗粒物,并起到气流均布作用。微生物群落以生物膜形式附着于填料表面,形成稳定的生态系统。当臭气分子扩散至生物膜时,特定菌种通过酶促反应将其作为营养源分解。例如,硫化氢被硫氧化细菌转化为硫酸盐,氨气经硝化作用转化为硝酸盐,挥发性脂肪酸则被异养菌矿化为二氧化碳和水。

The packing layer is the core reaction zone of the filter tank, usually composed of porous inert materials such as ceramic particles, volcanic rocks, or composite organic carriers. These materials not only provide attachment surfaces for microorganisms, but their pore structure can also trap particles in the gas and achieve uniform airflow distribution. Microbial communities attach to the surface of fillers in the form of biofilms, forming a stable ecosystem. When odor molecules diffuse to the biofilm, specific bacterial species use enzymatic reactions to decompose them as a source of nutrients. For example, hydrogen sulfide is converted into sulfate by sulfur oxidizing bacteria, ammonia is converted into nitrate by nitrification, and volatile fatty acids are mineralized into carbon dioxide and water by heterotrophic bacteria.

生物降解过程的效率受环境参数影响显著。温度需控制在20-40℃之间,多数中温微生物在此区间活性最佳;湿度需维持60%-90%,过干会导致微生物失活,过湿则引发填料板结;pH值需根据处理对象调整,如含硫臭气处理需保持微碱性环境以促进硫酸盐生成。此外,营养物质的均衡供给至关重要,当臭气中碳源不足时,需补充甲醇或葡萄糖等有机物,而氮磷缺乏则需添加尿素或磷酸盐。

The efficiency of biodegradation process is significantly influenced by environmental parameters. The temperature should be controlled between 20-40 ℃, and most mesophilic microorganisms have the best activity in this range; The humidity should be maintained at 60% -90%. Excessive dryness can lead to microbial inactivation, while excessive humidity can cause packing compaction; The pH value needs to be adjusted according to the treatment object, such as maintaining a slightly alkaline environment for sulfur-containing odor treatment to promote sulfate generation. In addition, a balanced supply of nutrients is crucial. When the carbon source in the odor is insufficient, organic substances such as methanol or glucose need to be supplemented, while nitrogen and phosphorus deficiency requires the addition of urea or phosphate.

气体在填料层中的停留时间直接影响处理效果,通常设计为15-60秒,需通过实验确定最佳空床停留时间。经过生物降解后的气体进入滤池顶部的除雾层,去除夹带的水分和微粒后排放。整个过程实现臭气物质的矿化,最终产物为无害的二氧化碳、水和无机盐类。

The residence time of gas in the packing layer directly affects the treatment effect, usually designed to be 15-60 seconds, and the optimal empty bed residence time needs to be determined through experiments. After biodegradation, the gas enters the dehazing layer at the top of the filter tank to remove entrained moisture and particles before being discharged. The entire process realizes the mineralization of odorous substances, and the final products are harmless carbon dioxide, water, and inorganic salts.

生物除臭滤池的运维重点包括填料定期更换、微生物群落监测与补菌、环境参数动态调控。随着运行时间延长,填料孔隙可能被无机盐沉积物堵塞,需通过反冲洗或部分更换恢复通透性。同时,需定期检测填料层微生物活性,当处理效率下降时,需投加针对性菌剂以强化特定污染物的降解能力。

The key points of operation and maintenance of the biological deodorization filter include regular replacement of fillers, monitoring and supplementing of microbial communities, and dynamic regulation of environmental parameters. As the running time prolongs, the pores of the packing material may be blocked by inorganic salt deposits, and permeability needs to be restored through backwashing or partial replacement. At the same time, it is necessary to regularly test the microbial activity of the packing layer. When the treatment efficiency decreases, targeted microbial agents need to be added to enhance the degradation ability of specific pollutants.

该技术的创新方向集中于填料改良、菌种筛选与智能控制。新型复合填料通过添加活性炭或纳米材料提升吸附容量,基因工程菌的应用则可突破传统微生物的处理极限。结合物联网技术,实时监测关键参数并自动调节环境条件,已成为提升滤池稳定性和处理效率的重要手段。

The innovation direction of this technology focuses on filler improvement, strain screening, and intelligent control. The new composite fillers can increase adsorption capacity by adding activated carbon or nanomaterials, and the application of genetically engineered bacteria can break through the processing limit of traditional microorganisms. Combining IoT technology, real-time monitoring of key parameters and automatic adjustment of environmental conditions has become an important means to improve the stability and treatment efficiency of filters.

本文由生物除臭设备友情奉献.更多有关的知识请点击:http://www.tdyhhb.com我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is a friendly contribution from catalytic combustion equipment For more information, please click: http://www.tdyhhb.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

截屏,微信识别二维码